We believe that the quality does not occur but it is built into the product through strict adherence to the approved procedures, trained work force and good atmosphere of working.

In addition to the procedures followed by the QC, stringent in-process checks are imposed and the results recorded, at every stage right from receiving of raw material to delivery of the finished goods. The manufacturing is conducted under controlled air filtering and handling system, in a clean room with Class 10000 standards and the filling is done in a steriled area with Class 100 standards at positive pressure with 30 to 40 air changes per minute.

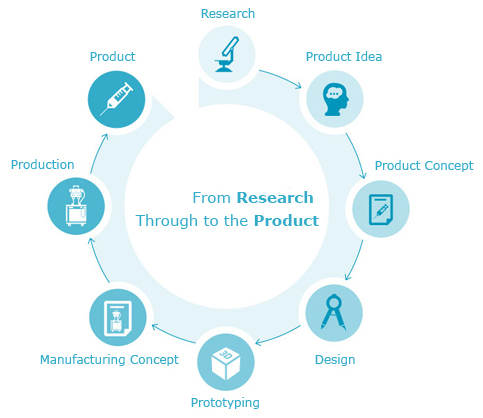

The entire activity is supported by detail documentation on the production process, flowchart, methods of in-process controls, and batch manufacturing records (BMR).

We strictly follow current Good Manufacturing Practices (cGMP) as guided by the World Health Organization (WHO), including compliance with national and international regulations, industry standards and customer requirements.

Cardiovascular

Cardiovascular